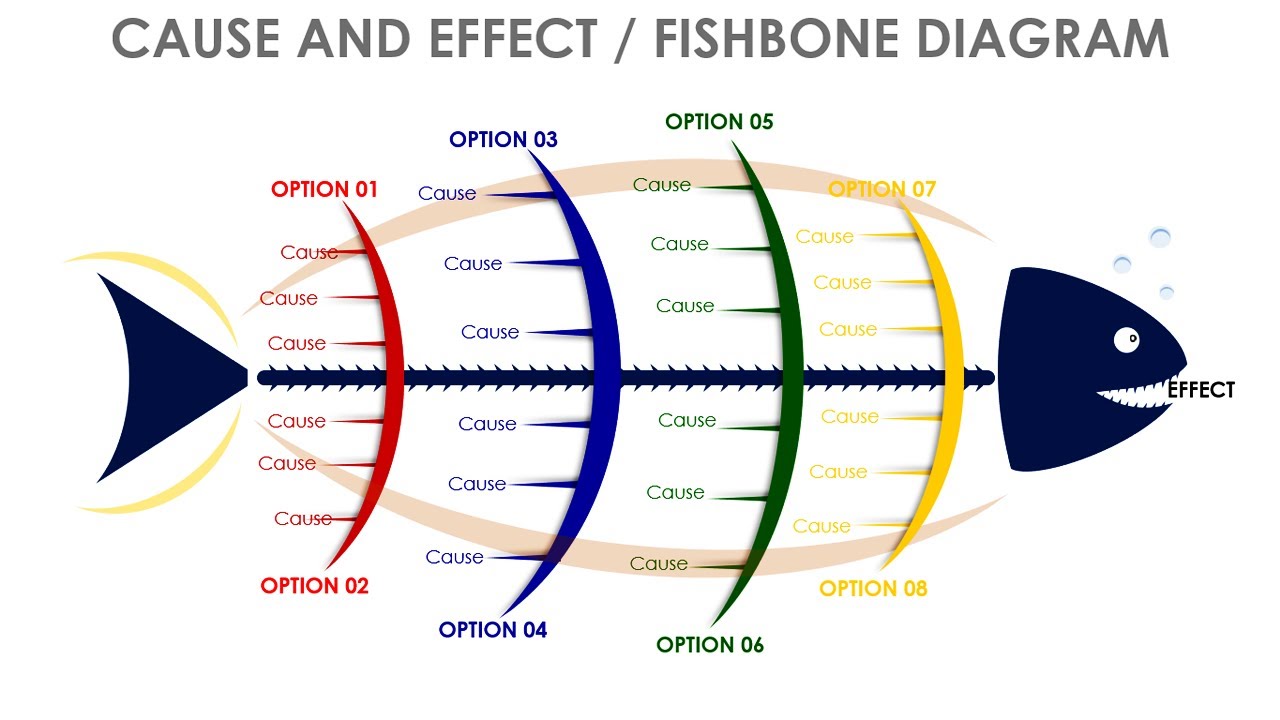

If your project team is fairly large, make sure to get input from team members who have experienced issues that you may not be aware of. When using a Fishbone diagram, follow a few best practices to get the most out of them. Example of Fishbone diagram in project management - 5M/1E This may be useful in a manufacturing environment as it includes material and machine categories. Here you may be able to identify critical supply chain disruptions, skills shortages, or process shortfalls.ĥM/1E Fishbone diagram: The categories in a 5M/1E Fishbone diagram stand for man, machine, method, material, measurement, and environment. This means that a project manager can exercise a great deal of flexibility in identifying factors specific to their particular project phases and environment.ĤS Fishbone diagram: The categories in a 4S Fishbone diagram are surroundings, suppliers, skills, and systems. It also does not include pre-labeled categories. Simple Fishbone diagram: A Simple Fishbone diagram does not have as many branches as the others. Three common types of Fishbone diagrams are the Simple, 4S, and 5M/1E Fishbone diagrams. What works in a creative environment may not work in a manufacturing environment, for example.

This is because projects can have major differences in processes, complexities, and more.

There are a few different types of Fishbone diagrams.

0 kommentar(er)

0 kommentar(er)